Cleaning & Sanitizing Brewing Equipment

concise method for cleaning & sanitizing - introduction to biofilms

Introduction: The amount of information on cleaning & sanitizing is mind boggling. I am going to focus on one cleaning chemical and one sanitizing chemical for this post. Both chemicals have been developed for the brewing industry. They are effective and relatively easy to use for home brewing

Cleaning: is the process of removing organic and inorganic contaminants to a level of insignificance. Washing agents are designed to facilitate this process by breaking down, solubilizing, and dispersing contaminants into water, so the contaminants can be washed away

Sanitation: is the process of eradicating living microorganisms down to an acceptable level (no observable effect on wine making). Sanitation is not sterilization

Cleaning Brewing Equipment

Powdered Brewery Wash (PBW)

PBW is very effective in removing thick, difficult, and caked-on organic soils.

Effective substitute for caustic soda cleaners and household cleaners.

Can clean items that cannot be reached with a brush or sponge by simply soaking and rinsing.

Safe on skin as well as stainless steel, rubber, soft metals, and on plastics.

Procedure:

Rinse off the surface to get rid of as much soil as possible.

Dissolve 1-2 ounces per gallon for kettles and 3/4 ounces per gallon for fermenters, kegs, tanks, and other equipment.

If soaking, heat to 140° and soak for 4 hours or allow to soak cold overnight.

for bottles, I use a brush attached to a drill for maximum agitation

Rinse surfaces

Sanitation of Brewing Equipment

Star San

A high foaming, acid-based, no-rinse sanitizer that is effective and easy to use.

Self-foaming, which helps to penetrate cracks and crevices.

Reduces water spotting and can be used without rinsing when used at the recommended dilution.

Procedure:

clean surfaces with PBW or compatible cleaner.

for soaking - mix 1 oz (30ml) Star San for every 5 gal. of water

for spraying - 1 Liter Spray Bottle - mix 1.5ml into 1 liter of water

allow for a contact time of at least 5 minutes.

drain

Manufacturer’s recommendations are no rinse.

I rinse sanitized equipment prior to use to minimize any Star San residues

Cleaning Carboys - low-effort method

Combining soaking with agitation is considerably more effective than soaking alone. First add about ¾ gallon (3 liters) of hot washing solution and close the carboy with a stopper that has an easily removable vent plug. Then, place the carboy sideways on a soft surface, such as an old piece of carpet, and slosh/roll back and forth. Stop every few minutes to release the suction that results as the warm water vapor cools and condenses.

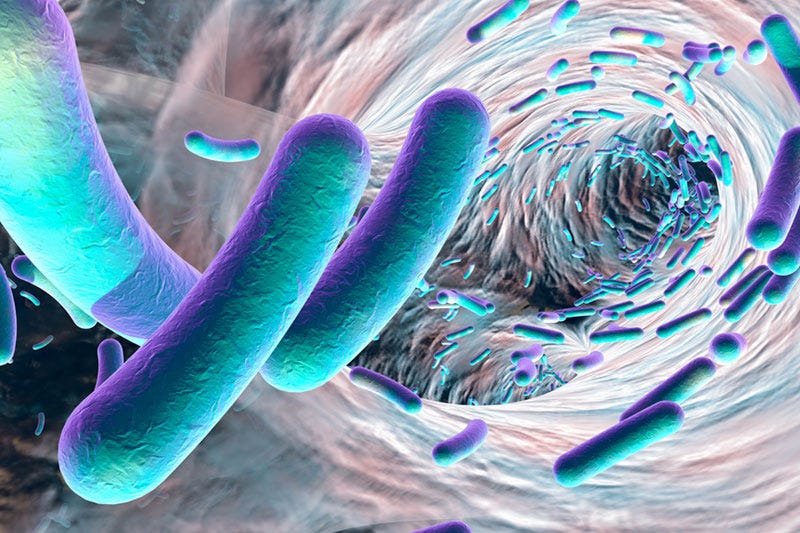

Biofilms

Biofilms are a significant concern in larger breweries that have clean in place systems for production equipment. In home breweries where equipment is disassembled and cleaned out of place, it is easier to prevent biofilms with a combination of aggressive cleaning tools and chemicals

“Biofilms are formed when bacteria attach to a surface such as that forming the beer line and then produce and encase themselves in a polysaccharide or slime matrix. When this happens, further bacterial growth cannot escape the matrix and so the biofilm grows”

“there are plenty of opportunities in beer lines and on other brewing surfaces for microorganisms (bacteria, yeast, and fungal cells) to adhere and build up”

Thanks for reading this article and following The Forager on substack.

Source of picture and quotes: https://actechinc.co/all-about-beer-lines-blog/biofilm-formation-breweries-beer